Showroom

Centrifugal force is used by a Centrifuge Machine to separate materials with varying densities. The rotor, motor, chamber, and control system are important parts. It comes in a variety of sizes and styles, including high-speed, tabletop, and floor-standing. It improves separation efficiency and streamlines procedures in sectors like food, medicine, and healthcare.

Stainless steel (SS) and silver in colour, the Bottom Discharge Centrifuge Machine runs at 1200 RPM with a 220-240V motor. The discharge valve and rotor are important parts. It guarantees effective separation, increased efficiency, and durability in sectors like chemicals, pharmaceuticals, and food processing.

A Pusher Centrifuge is a machine designed for solid-liquid separation, featuring a rotating drum and a pusher plate. Made of stainless steel, it operates efficiently in industries like chemicals, pharmaceuticals, and mining. Its design ensures continuous operation, improving productivity, reducing waste, and enhancing separation performance for various industrial applications.

An industrial centrifuge uses rotational force to separate materials by density. Key components include the rotor, motor, bowl, and control system. Used in industries like pharmaceuticals, chemicals, food, and wastewater, types include disc stack, tubular, and basket centrifuges. Benefits include cost savings, improved quality, high performance, and durability.

Basket centrifuges are industrial machines used for separating solids from liquids. Key components include the basket, motor, gearbox, and drive mechanism. Available in various sizes, they are used in food, chemical, pharmaceutical, and mining industries. Types include horizontal and vertical models. They offer high performance, durability, and efficiency, benefiting businesses with precise separation and reduced waste.

Manual Top Discharge Centrifuges are machines used for separating solid and liquid phases. Key components include the basket, motor, and discharge valve. Available in various sizes, they are commonly used in chemical, pharmaceutical, and food industries. Their manual discharge process offers reliability, simplicity, and cost-effectiveness in solid-liquid separation.

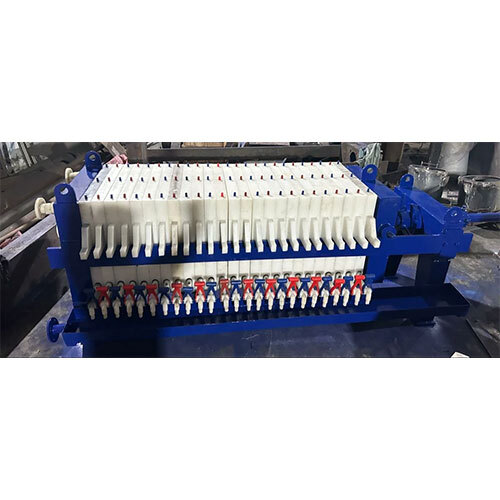

A Filter Press Machine is used for solid-liquid separation in industries like chemical, pharmaceutical, and food. It consists of plates, frames, filter cloths, and hydraulic mechanisms. Available in various sizes, it ensures efficient filtration, providing high performance and strength. Its design enhances productivity, offering cost-effective, reliable, and customizable solutions for businesses.

A storage tank is a container that is used to hold gases or liquids. It is composed of carbon steel or stainless steel and has parts like gauges, valves, and pressure relief systems. It is widely used in sectors such as oil, chemicals, and food processing for secure, effective storage and convenient access. It comes in a variety of sizes and styles, such as vertical and horizontal.

The Limpet Coil Vessel is an ancient ceramic vessel characterized by its coiled construction and distinctive limpet shell-shaped design. Typically associated with prehistoric cultures, it features a spiral pattern, which may have had symbolic or functional significance. The vessel's unique form highlights early craftsmanship and material use in pottery.

A reactor vessel is a key component in nuclear power plants, designed to contain nuclear reactions. It houses the reactor core, where fuel rods undergo fission, generating heat. The vessel is built to withstand high pressure and temperature, ensuring safe containment of radioactive materials during energy production.

A mixing tank is a crucial industrial equipment used to blend liquids, solids, or gases. It features an agitator or mixer to ensure uniform consistency. Key factors include capacity, material (often stainless steel), and mixing efficiency. Mixing tanks are essential in industries like food processing, chemicals, and pharmaceuticals.

A hydro extractor is a device that uses centrifugal force to remove extra water from materials, usually chemicals or textiles. It is made up of a motor, basket, and revolving drum. It is frequently utilised in the laundry and textile sectors to increase drying effectiveness, shorten processing times, and improve product quality.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free